#electronics contract manufacturing

Explore tagged Tumblr posts

Text

Top Contract Electronic Manufacturing Services

Discover top-tier contract electronic manufacturing services with East West Manufacturing Enterprises. Specializing in PCB assembly and complete product builds, we combine precision, quality, and efficiency to meet your manufacturing needs. Count on us for reliable solutions that ensure your products are built to the highest standards, helping you bring innovative ideas to market with confidence. Explore how our expertise can streamline your manufacturing process today!

#east west manufacturing austin#electronics manufacturers#electronics contract manufacturing#electronics manufacturing services#aerospace and defense manufacturing#defense electronics manufacturing#aftermarket services#east west electronics#integration system#system integration testing#Military Electronics Manufacturers#Electronic Contract Manufacturing Services#Contract Electronic Manufacturing Services#Cable and Wire Harness Assembly Services#Contract Electronic Manufacturing#Functional Testing Austin#Printed Circuit Board Assembly

0 notes

Text

HDI PCB & High Interconnect PCB Manufacturing

HDI PCB Manufacturer & Assembly – One-stop service

What is a high density PCB board (HDI PCB)?

The HDI board is based on the traditional double panel as the core board, which is made by continuously accumulating. This circuit board made by a continuous layer is also called the Build-Up Multilayer (BUM). Compared with the traditional circuit board, the HDI circuit board has the advantages of "light, thin, short, small".

The electrical connection between HDI's plate layer is achieved by conductive pores, buried holes, and blind holes. Its structure is different from ordinary multi -layer circuit boards. A large number of blind holes are used in HDI boards. HDI PCB uses laser direct drilling, and standard PCB usually uses mechanical drilling, so the number of layers and high width ratio often decreases.

HDI includes the use of fine features or signal traces and spaces of 0.003” (75 µm) or less and laser-drilled blind or buried microvia technology. Microvias allow the use of micro-interconnects from one layer to another within a PCB utilizing a smaller pad diameter creating additional routing density or reducing form factor.

High-density interconnect (HDI) PCBs are characterized by finer lines, closer spaces, and more dense wiring, which allow for a faster connection while reducing the size and bulk of a project. These boards also feature blind and buried vias, laser ablated microvias, sequential lamination, and via in-pads. As a result, a HDI board can house the functionality of the previous boards used. HITECH CIRCUITS is an HDI PCB manufacturer and provider in Shenzhen, China supports HDI PCB prototype and mass production with less expensive price and quick-turn lead time. Customers from a variety of industries we serve have a common that have high expectations in quality, reliability and on-time delivery in HDI PCB production. Our quality is not afterthought, but built into each process from front-end to fabrication and shipping.

HDI PCB's Advantages

1. Reduce PCB cost: When the density of PCB increases beyond the eight-layer board, it will be manufactured in HDI, and the cost will be lower than that of traditional complicated press-forming process.

2. Better reliability: Due to the thin thickness and the aspect ratio of 1:1, the micropores have higher reliability when transmitting signals than ordinary through holes.

3. Improves thermal properties: The insulating dielectric material of the HDI board has a higher glass transition temperature (Tg) and therefore has better thermal properties.

4. Improve RF interference / electromagnetic interference / electrostatic discharge (RFI / EMI )

5. Increase design efficiency: Micro-hole technology allows the circuit to be arranged in the inner layer, so that the circuit designer has more design space, so the efficiency of the line design can be higher.

HDI PCB Manufacturing Process

The overall process for manufacturing HDI PCB is essentially the same as for fabricating other PCB board, with notable differences for PCB stack-up and hole drilling. Since HDI boards generally require smaller drill holes for vias, laser drilling is usually required. Although laser drills can produce smaller and more precise holes, they are limited by depth. Therefore, a limited number of layers can be drilled through at a time. For HDI boards, which are invariably multilayer and may contain buried and blind vias, multiple drilling processes may be required. This necessitates successive layer boding to achieve the desired stack-up or sequential lamination cycles. Not surprisingly, this can significantly increase PCB manufacturing time and cost. HDI PCB fabrication is an advanced technology and therefore requires expertise along with specialized equipment like laser drills, laser direct imaging (LDI) capability, and special clean room environments. In order to efficiently manufacture high-quality and reliable HDI PCB products, you must understand the HDI board manufacturing process and coordinate with your HDI PCB supplier to implement good DFM (Design for Manufacturability) for HDI layout design. Therefore, not all board factories have the ability to do the HDI, but Hitechpcb can, we will be here to support our customer needs.

-Consumer Driven Technology

The via - in - pad process supports

More technology on fewer layers, proving that bigger is not always better. Since the late 1980's we have seen video cameras using cartridges the size of a novel, shrink to fit in the palm of your hand. Mobile computing and work at home have further promoted technology to make the computer faster and lighter, allowing consumers to do remote work from anywhere.

HDI technology is the main reason for these changes. The products do more, weigh less, and their bodies are smaller. Professional equipment, mini components and thinner materials reduce the size of electronic equipment, while expanding technology, quality and speed.

-Via in Pad Process

The inspiration from the surface installation technology pushed the restrictions of BGA, COB and CSP to a smaller square surface inch. The via in pad can be placed in the surface of flat land through the cushion process. The via is plated and filled with conductive or non-conductive epoxy resin, and then close and plat it to make it almost invisible.

It sounds simple, but there are eight steps to complete this unique process. Professional equipment and well -trained technicians followed closely to achieve perfect hiding.

-Via Fill Types

There are many different types of via fill materials: non -conductive epoxy, epoxy, copper filling, filling and electrochemical coating. All this leads to via buried in a flat land, and the land will be fully solders as normal land. Vias and mricrovias are drilled, blind or buried, plated, and then hidden under the SMT land. Processing vias of this type of Vias requires special devices and takes time. The process time of multiple drill cycles and controlling deep drills has increased.

-Cost Effective HDI

Although the size of some consumer products is reduced, quality is still the most important factor for consumers. Use HDI technology during the design process, you can reduce the 8-layer through-hole PCB to a 4 layer HDI Microvia technology packed PCB. The elaborate HDI 4-layer PCB wiring function can achieve the same or better functions as standard 8-layer PCB.

Although the Microvia process has increased the cost of HDI PCB, the appropriate design and decrease of layers of counting reduces the cost of the ingredients of the material, and the layer count is large.

-Laser Drill Technology

The smallest micro-vias can provide more technologies on the surface of the plate. Using a beam with a diameter of 20 microns (1 mil), this high impact can be cut through metal and glass to produce tiny via hole. There are new products, such as uniform glass materials, and they are low -loss layer pressure plates and low -dielectric constants. These materials have high heat resistance, can be used for lead -free components, and allows smaller holes.

-Lamination & Materials For HDI PCB Boards

Advanced multilayer technology allows designers to add other layers to form a multilayer PCB. Use laser drills to produce holes in the inner layer, and can be coated when pressed, imaging and etching. The process of this increase is called sequential construction. Hitechpcb HDI PCB manufacturing uses solid -filled VIA can better heat management, connect stronger connection and improve the reliability of the board.

The copper of the resin coating is a assistant with poor pores, with longer drilling time and thinner. Hitechpcb has ultra low contours and ultra thin copper foil, and its surface is fixed on a tiny nodule. This material has chemically treated and started chemical treatment and startup of the most fine and high quality lines and spacing technology.

The dry resistance of the layer pressure plate still uses heating scroll method to apply resistance to core materials. It is now recommended to preheat the material to the required temperature before the layer pressure process of the HDI printing circuit board. The preheating of the material can better apply dry resistance to the surface of the layer pressure plate, pull less calories from the heat roll, and keep the stable export temperature of the layer made products consistent. The consistent entrance and exit temperature cause less air clips under the movie. This is essential for the breeding of fine lines and spacing.

How difficult is the HDI Printed Circuits Board?

The manufacturing of the HDI PCB (High Denity PCB) is relatively difficult because it needs to use complex manufacturing technique and technology. The following is some difficulties made by HDI PCB:

Multi-layer plate lamination: HDI Printed Circuits Boards are usually composed of multi-layer boards, and multi-layer boards need to be laminated. Multi-layer plates need to control parameters such as temperature, time, pressure to ensure the control quality and thickness control between multi-layer boards.

Blind holes and buried holes: HDI Printed Circuits Boards need to create blind holes and buried holes, which requires technologies such as laser drilling and chemical corrosion to ensure the accuracy and quality of the hole.

Impedance control: HDI Printed Circuit Boards need to control impedance, which requires fine design of the layout and circuit of the circuit board, and uses special materials and processes to achieve impedance control.

Small track space manufacturing: HDI Printed Circuits Boards need to make very small spacing tracks (conductions), which requires high-precision manufacturing equipment and technologies to ensure the accuracy and quality of the circuits.

The difference between HDI board and normal PCB

The HDI board is generally made of accumulation method. The more times the accumulation layer, the higher the technical grade of the board. Ordinary HDI boards are basically one accumulation. The high-end HDI uses two or more accumulated technologies, and at the same time, advanced PCB technology such as stacked holes, plating filling, and laser direct punching. When the density of PCB increases more than eight layers board, it is made by HDI, and its cost will be lower than the traditional complex compact process.

The electrical performance and signal of the HDI board are higher than that of traditional PCB. In addition, HDI boards have improved better for radio frequency interference, electromagnetic wave interference, electrostatic release, and thermal conduction. High density integration (HDI) technology can make terminal product design more miniaturized, while meeting higher standards for electronic performance and efficiency.

The HDI board uses a blind hole plating to perform secondary pressure, divided into one order, second order, third order, fourth, fifth order, etc. The first order is relatively simple, and the processes and processes are easy to control. The main problem of the second order is the issue of the place, and the other is the problem of punching and copper plating. There are many second order design. One is the wrong position of each order. When connecting the secondary neighborhood, it is connected to the middle layer through the wire. The method is equivalent to two first order HDI. The second is that the two order holes are overlapped. The second -order is realized by the superposition method. The processing is similar to the two first order, but there are many key points of the process. The third type is to punch perforation directly from the outer layer to the third layer (or N-2 layer). There are many different techniques from the front, and the difficulty of punching is even more difficult.

In PCB proofing, HDI costs high, so general PCB proofing manufacturers are unwilling to do it. HITECHPCB can be a HDI Blind PCB board that others are unwilling to do. At this stage, the HDI technology adopted by HITECH has exceeded the highest number of layers of 20 layers; the number of blind holes is 1st to 4th; the minimum pore diameter is 0.076mm, and the process is laser drilling.

HDI PCB Manufacturer & Assembly – One-stop services from China

-HDI (high-density interconnection board) is a compact circuit board designed for small capacity users. Compared with ordinary PCB, the most significant feature of HDI is that the wiring density is high.

HDI PCB Manufacturer & Assembly – One-stop service The HDI PCB��is defined as a micro via with a hole diameter of 6 mils or less and a hole diameter of 0.25 mm or less. The contact density is above 130 points/square, and the wiring density is with a line width/pitch of 3 mil/3 mil or less. HDI PCB, the full name is High Density Interconnect PCB, it requires much higher wiring density with finer trace and spacing, smaller vias and higher connection pad density. Blind and buried vias’ design is one of their marked feature. HDI PCB board is widely used in Cell phone, tablet computer, digital camera mother board PCB, GPS, Automobile board, LCD module and other different area.

HDI pcb is the abbreviation for High Density Interconnect pcb or High Density pcb. An HDI PCB is defined as a printed circuit board with a higher wiring density per unit area than a conventional PCB. Hitech Circuits Co., Limited is a professional high density interconnect pcbs, HDI pcb board manufacturer, supplier and design company from China, if you are looking for reliable high density interconnect PCB board partner from China, please don’t hesitate to contact [email protected]

0 notes

Text

𝐃𝐢𝐬𝐜𝐨𝐯𝐞𝐫 𝐭𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐄𝐕 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠!

The electric vehicle revolution is here, and efficiency is the key to driving the future of mobility. Our latest insights reveal the groundbreaking strategies that are not only reducing costs but also pushing the boundaries of productivity in EV component manufacturing. Want to be part of the next big thing in EVs? This is a must-read! Read more here: https://www.avalontec.com/blog/optimizing-ev-manufacturing/

#EVManufacturing#ElectricVehicles#Innovation#FutureOfMobility#GreenTech#ManufacturingTrends#EV#electronics#quality#electronic manufacturer#ems company#industry#usa#manufacturing#electronic contract manufacturing#ems industry#EV Components Manufacturing

0 notes

Text

🗣️THIS IS WHAT INCLUSIVE, COMPASSIONATE DEMOCRACY LOOKS LIKE

Minnesota Dems enacted a raft of laws to make the state a trans refuge, and ensure people receiving trans care here can't be reached by far-right governments in places like Florida and Texas. (link)

Minnesota Dems ensured that everyone, including undocumented immigrants, can get drivers' licenses. (link)

They made public college free for the majority of Minnesota families. (link)

Minnesota Dems dropped a billion dollars into a bevy of affordable housing programs, including by creating a new state housing voucher program. (link)

Minnesota Dems massively increased funding for the state's perpetually-underfunded public defenders, which lets more public defenders be hired and existing public defenders get a salary increase. (link)

Dems raised Minnesota education spending by 10%, or about 2.3 billion. (link)

Minnesota Dems created an energy standard for 100% carbon-free electricity by 2040. (link)

Minnesota already has some of the strongest election infrastructure (and highest voter participation) in the country, but the legislature just made it stronger, with automatic registration, preregistration for minors, and easier access to absentee ballots. (link)

Minnesota Dems expanded the publicly subsidized health insurance program to undocumented immigrants. This one's interesting because it's the sort of things Dems often balk at. The governor opposed it! The legislature rolled over him and passed it anyway. (link)

Minnesota Dems expanded background checks and enacted red-flag laws, passing gun safety measures that the GOP has thwarted for years. (link)

Minnesota Dems gave the state AG the power to block the huge healthcare mergers that have slowly gobbled up the state's medical system. (link)

Minnesota Dems restored voting rights to convicted felons as soon as they leave prison. (link)

Minnesota Dems made prison phone calls free. (link)

Minnesota Dems passed new wage protection rules for the construction industry, against industry resistance. (link)

Minnesota Dems created a new sales tax to fund bus and train lines, an enormous victory for the sustainability and quality of public transit. Transit be more pleasant to ride, more frequent, and have better shelters, along more lines. (link)

They passed strict new regulations on PFAS ("forever chemicals"). (link)

Minnesota Dems passed the largest bonding bill in state history! Funding improvements to parks, colleges, water infrastructure, bridges, etc. etc. etc. (link)

They're going to build a passenger train from the Twin Cities to Duluth. (link)

I can't even find a news story about it but there's tens of millions in funding for new BRT lines, too. (link)

A wonky-but-important change: Minnesota Dems indexed the state gas tax to inflation, effectively increasing the gas tax. (link)

They actually indexed a bunch of stuff to inflation, including the state's education funding formula, which helps ensure that school spending doesn't decline over time. (link)

Minnesota Dems made hourly school workers (e.g., bus drivers and paraprofessionals) eligible for unemployment during summer break, when they're not working or getting paid. (link)

Minnesota Dems passed a bunch of labor protections for teachers, including requiring school districts to negotiate class sizes as part of union contracts. (Yet another @SydneyJordanMN special here. (link)

Minnesota Dems created a state board to govern labor standards at nursing homes. (link)

Minnesota Dems created a Prescription Drug Affordability Board, which would set price caps for high-cost pharmaceuticals. (link)

Minnesota Dems created new worker protections for Amazon warehouse workers and refinery workers. (link)

Minnesota Dems passed a digital fair repair law, which requires electronics manufacturers to make tools and parts available so that consumers can repair their electronics rather than purchase new items. (link)

Minnesota Dems made Juneteenth a state holiday. (link)

Minnesota Dems banned conversion therapy. (link)

They spent nearly a billion dollars on a variety of environmental programs, from heat pumps to reforestation. (link)

Minnesota Dems expanded protections for pregnant and nursing workers - already in place for larger employers - to almost everyone in the state. (link)

Minnesota Dems created a new child tax credit that will cut child poverty by about a quarter. (link)

Minnesota Democrats dropped a quick $50 million into homelessness prevention programs. (link)

And because the small stuff didn't get lost in the big stuff, they passed a law to prevent catalytic converter thefts. (link)

Minnesota Dems increased child care assistance. (link)

Minnesota Dems banned "captive audience meetings," where employers force employees to watch anti-union presentations. (link)

No news story yet, but Minnesota Dems forced signal priority changes to Twin Cities transit. Right now the trains have to wait at intersections for cars, which, I can say from experience, is terrible. Soon that will change.

Minnesota Dems provided the largest increase to nursing home funding in state history. (link)

They also bumped up salaries for home health workers, to help address the shortage of in-home nurses. (link)

Minnesota Dems legalized drug paraphernalia, which allows social service providers to conduct needle exchanges and address substance abuse with reduced fear of incurring legal action. (link)

Minnesota Dems banned white supremacists and extremists from police forces, capped probation at 5 years for most crimes, improved clemency, and mostly banned no-knock warrants. (link)

Minnesota Dems also laid the groundwork for a public health insurance option. (link)

I’m happy for the people of Minnesota, but as a Floridian living under Ron DeSantis & hateful Republicans, I’m also very envious tbh. We know that democracy can work, and this is a shining example of what government could be like in the hands of legislators who actually care about helping people in need, and not pursuing the GOP’s “culture wars” and suppressing the votes of BIPOC, and inflicting maximum harm on those who aren’t cis/het, white, wealthy, Christian males. BRAVO MINNESOTA. This is how you do it! And the Minnesota Dems did it with a one seat majority, so no excuses. Forget about the next election and focus on doing as much good as you can, while you still can. 👏🏿👏🏿👏🏿👏🏿👏🏿👏🏿👏🏿

👉🏿 https://threadreaderapp.com/thread/1660846689450688514.html

#politics#minnesota#social justice#culture wars#this is what democracy looks like#republicans are evil

25K notes

·

View notes

Link

Decoding OEM: Unraveling the Mystery Behind the Acronym When it comes to the world of manufacturing and technology, the term "OEM" often pops up. OEM stands for Original Equipment Manufacturer and plays a significant role in various industries. In this article, we will delve into the concept of OEM, employing the MECE (Mutually Exclusive, Collectively Exhaustive) Framework to provide a comprehensive understanding of its implications and significance. [caption id="attachment_62824" align="aligncenter" width="800"] what does OEM stand for[/caption] Understanding OEM What Does OEM Stand For? OEM stands for Original Equipment Manufacturer. It refers to a company that produces components or products that are used in the manufacturing of another company's end product. The term "equipment" refers to the physical or digital parts, devices, or software that are integrated into the final product by the OEM. The Role of OEM in Different Industries OEM is prevalent in various industries, including automotive, electronics, software, and more. In these sectors, OEM ensures that the products manufactured by different companies meet the required quality, reliability, and compatibility standards. OEM plays a crucial role in maintaining consistency and standardization within the industry. OEM vs. Aftermarket: Key Differences OEM products are different from aftermarket products. OEM components are produced by the original manufacturer of the end product, ensuring a high level of quality, compatibility, and warranty. Aftermarket products, on the other hand, are produced by third-party manufacturers and may not meet the same quality standards as OEM products. While aftermarket products may be cheaper, they often lack the same level of reliability and compatibility as OEM products. OEM in Practice OEM in the Automotive Industry In the automotive industry, OEM components are seamlessly integrated into vehicles during the manufacturing process. These components, such as engines, transmissions, and electronic systems, are specifically designed and manufactured by the original vehicle manufacturer. Using OEM parts in vehicles ensures optimal performance, warranty coverage, and safety. OEM parts are built to the exact specifications of the vehicle, providing a perfect fit and maintaining the integrity of the vehicle's design. OEM in the Electronics Industry The electronics industry heavily relies on OEM components to create various devices. OEM electronics, such as integrated circuits, displays, and sensors, are designed and produced by the original manufacturer. These components are known for their compatibility with the devices they are intended for, ensuring reliable performance and seamless integration. Using OEM electronics in devices enhances their functionality and reliability, as they are specifically engineered to work harmoniously with the overall system. OEM in the Software Industry In the software industry, OEM software refers to software packages that are licensed by original manufacturers to be bundled with other products or services. OEM software is often pre-installed on computers, smartphones, or other electronic devices. It provides users with a legitimate and authorized version of the software, along with regular updates and technical support. OEM software is an integral part of the overall user experience, offering enhanced functionality and compatibility. FAQs: What are the advantages of choosing OEM products? Choosing OEM products comes with several advantages. OEM products are known for their high quality, as they are produced by the original manufacturer and designed to meet specific standards. They offer compatibility with the intended system, ensuring seamless integration and optimal performance. Additionally, OEM products often come with warranties, providing peace of mind to consumers. Are OEM products more expensive than aftermarket alternatives? OEM products may be slightly more expensive than aftermarket alternatives due to their higher quality and compatibility. However, it is important to consider the long-term benefits of choosing OEM, such as better performance and reliability. The cost difference is often justified by the enhanced user experience and reduced risk of compatibility issues. Can OEM parts be used to upgrade existing products? Yes, OEM parts can be used to upgrade existing products in many cases. OEM manufacturers often provide compatible upgrade options for their products, allowing users to enhance the performance or functionality of their devices. Whether it's upgrading a vehicle with OEM performance parts or upgrading a computer with OEM components, using OEM parts ensures compatibility and maintains the integrity of the original product design. However, it's important to check the compatibility and specifications provided by the OEM to ensure a successful upgrade. How can consumers identify OEM products? Identifying genuine OEM products can be crucial to ensure quality and compatibility. Here are a few tips: Check the packaging and labels for the OEM branding and logos. Look for authorized OEM retailers or purchase directly from the OEM's official website. Read product descriptions and specifications to ensure they match the OEM's official information. Verify the warranty and support provided, as OEM products usually come with manufacturer-backed warranties. Is OEM limited to physical products, or does it extend to services as well? While OEM is commonly associated with physical products, it can also extend to services. In service-oriented industries, OEM refers to companies that provide specialized services or solutions to other businesses. These OEM service providers offer expertise, resources, and support to help other companies enhance their operations or deliver specific services. For example, in the IT industry, OEM service providers may offer white-label services or customized solutions that can be resold by other businesses under their brand. Conclusion: OEM, or Original Equipment Manufacturer, is a fundamental concept in various industries. Understanding OEM helps us recognize the importance of quality, compatibility, and standardization in the products and services we use. Whether it's automotive, electronics, software, or other sectors, OEM plays a crucial role in ensuring optimal performance, reliability, and customer satisfaction. By choosing OEM products, consumers can enjoy the benefits of high-quality components and seamless integration, ultimately enhancing their overall experience. So, the next time you make a purchasing decision, consider the value that OEM brings to the table.

#appliances#assembly#Automotive#branding#components#computers#contracts#customization#devices#distribution#electronics#hardware#industry#machinery#manufacturing#OEM#Original_Equipment_Manufacturer#outsourcing#Partnerships#parts#production#products#software#specifications#suppliers#technology#telecommunications

0 notes

Text

https://www.maximizemarketresearch.com/market-report/electronic-contract-manufacturing-and-design-services-market/23593/

The electronic contract manufacturing and design services concentrate primarily on technologies and sub-technologies such as computers, consumer devices, networking, servers and storage, telecommunications, and peripherals.

#Electronic Contract Manufacturing and Design Services Market#Electronic Contract Manufacturing and Design Services Market growth

0 notes

Text

Top 10 PCB Manufacturers in the World: A Comprehensive Guide

Introduction

In today's technologically advanced world, printed circuit boards (PCBs) play a crucial role in powering various electronic devices. From smartphones and laptops to medical equipment and automotive systems, PCBs serve as the backbone of modern technology. With the increasing demand for high-quality PCBs, it's essential to know about the top manufacturers in the world. This comprehensive guide will explore the top 10 PCB manufacturers globally, shedding light on their expertise, capabilities, and contributions to the industry.

PCB Manufacturing Industry: An Overview

Before delving into the top 10 PCB manufacturers, let's first understand the PCB manufacturing industry as a whole. PCBs are vital components that provide electrical connections and mechanical support for various electronic components. They are made by laminating thin layers of copper onto a non-conductive substrate, usually made of fiberglass or composite epoxy materials.

PCBs can have multiple layers, each serving a specific purpose. The manufacturing process involves intricate steps such as designing the PCB layout, etching the copper layers, drilling holes, and applying solder mask and silkscreen for labeling.

The PCB manufacturing industry is highly competitive and driven by innovation. With advancements in technology, manufacturers are constantly pushing the boundaries to produce PCBs that are smaller, more efficient, and capable of supporting complex electronic designs.

Now, let's dive into the top 10 PCB manufacturers in the world and explore their unique strengths and contributions.

ACME Circuits — We are the best-printed circuit board manufacturer and services providers. We provide high-quality PCB assembly, PCB design, PCB fabrication, PCB layout, PCB programming, testing, etc.

2. Foxconn Technology Group

3. TTM Technologies

4. Tripod Technology Corporation

5. Unimicron Technology Corporation

6. Zhen Ding Technology Holding

7. Nippon Mektron

8. Sumitomo Electric Industries

9. Young Poong Electronics

10. Samsung Electro-Mechanics

Conclusion

Choosing the right PCB manufacturer is paramount to the success of any electronic product. The top 10 PCB manufacturers in the world mentioned in this article have demonstrated their expertise, reliability, and commitment to delivering high-quality PCB solutions. Whether you prioritize innovation, customization, sustainability, or scalability, these manufacturers offer a diverse range of options to suit your specific requirements. By partnering with a reputable and trusted PCB manufacturer, you can ensure the seamless integration of PCBs into your electronic devices, ultimately enhancing their performance and reliability.

#Printed Circuit Board Manufacturers#pcb manufacturing#printed circuit board assembly#circuit board manufacturing#pcb board manufacturer#high frequency pcb manufacturing#printed circuit board manufacturers near me#pcb manufacturer#pcb supplier#pcb assembly services#pcb assembly manufacturer#electronic cable assembly#electronic contract services#pcb exporters#printed circuit board manufacturer in india#pcb manufacturing companies in india

1 note

·

View note

Text

Aaloktronix is a leading Electronic Contract Manufacturer (ECM) located in Seattle, USA. Our main focus is on delivering innovative solutions in PCB Design, PCB Assembly, Wire-cable Harness assembly, Material Procurement/BOM Scrub, Prototype Assembly/PCBA, Turn-key PCB Assembly, Quick Turn Assembly, and more. For more information visit https://aaloktronix.com/

0 notes

Text

East West Electronics Assembly Manufacturing Enterprises

East West Manufacturing Enterprises specializes in delivering premium electronic assemblies and custom cables to a wide range of industries worldwide. Known for precision and reliability, their solutions are tailored to meet the unique needs of each client. With a strong focus on quality and innovation, East West Manufacturing Enterprises ensures seamless integration and superior performance in every product they produce. Their commitment to excellence makes them a trusted partner in the global electronics industry.

#east west manufacturing austin#electronics manufacturers#electronics contract manufacturing#electronics manufacturing services#aerospace and defense manufacturing#defense electronics manufacturing#aftermarket services#east west electronics#integration system#system integration testing

0 notes

Text

GF365 is the leading and reliable custom manufacturer of electronic devices. GF365 is also the Global authorized electronic suppliers for more numbers of industry-leading brands.

Expert team is highly specialized in the rapid introduction of the newest products and technologies. GF365 is the best marketplace where you can easily source and buy raw materials of all sizes. It involves targeting the design engineers as well as buyer communities.

0 notes

Text

Athletes Go for the Gold with NASA Spinoffs

NASA technology tends to find its way into the sporting world more often than you’d expect. Fitness is important to the space program because astronauts must undergo the extreme g-forces of getting into space and endure the long-term effects of weightlessness on the human body. The agency��s engineering expertise also means that items like shoes and swimsuits can be improved with NASA know-how.

As the 2024 Olympics are in full swing in Paris, here are some of the many NASA-derived technologies that have helped competitive athletes train for the games and made sure they’re properly equipped to win.

The LZR Racer reduces skin friction drag by covering more skin than traditional swimsuits. Multiple pieces of the water-resistant and extremely lightweight LZR Pulse fabric connect at ultrasonically welded seams and incorporate extremely low-profile zippers to keep viscous drag to a minimum.

Swimsuits That Don’t Drag

When the swimsuit manufacturer Speedo wanted its LZR Racer suit to have as little drag as possible, the company turned to the experts at Langley Research Center to test its materials and design. The end result was that the new suit reduced drag by 24 percent compared to the prior generation of Speedo racing suit and broke 13 world records in 2008. While the original LZR Racer is no longer used in competition due to the advantage it gave wearers, its legacy lives on in derivatives still produced to this day.

Trilion Quality Systems worked with NASA’s Glenn Research Center to adapt existing stereo photogrammetry software to work with high-speed cameras. Now the company sells the package widely, and it is used to analyze stress and strain in everything from knee implants to running shoes and more.

High-Speed Cameras for High-Speed Shoes

After space shuttle Columbia, investigators needed to see how materials reacted during recreation tests with high-speed cameras, which involved working with industry to create a system that could analyze footage filmed at 30,000 frames per second. Engineers at Adidas used this system to analyze the behavior of Olympic marathoners' feet as they hit the ground and adjusted the design of the company’s high-performance footwear based on these observations.

Martial artist Barry French holds an Impax Body Shield while former European middle-weight kickboxing champion Daryl Tyler delivers an explosive jump side kick; the force of the impact is registered precisely and shown on the display panel of the electronic box French is wearing on his belt.

One-Thousandth-of-an-Inch Punch

In the 1980s, Olympic martial artists needed a way to measure the impact of their strikes to improve training for competition. Impulse Technology reached out to Glenn Research Center to create the Impax sensor, an ultra-thin film sensor which creates a small amount of voltage when struck. The more force applied, the more voltage it generates, enabling a computerized display to show how powerful a punch or kick was.

Astronaut Sunita Williams poses while using the Interim Resistive Exercise Device on the ISS. The cylinders at the base of each side house the SpiraFlex FlexPacks that inventor Paul Francis honed under NASA contracts. They would go on to power the Bowflex Revolution and other commercial exercise equipment.

Weight Training Without the Weight

Astronauts spending long periods of time in space needed a way to maintain muscle mass without the effect of gravity, but lifting free weights doesn’t work when you’re practically weightless. An exercise machine that uses elastic resistance to provide the same benefits as weightlifting went to the space station in the year 2000. That resistance technology was commercialized into the Bowflex Revolution home exercise equipment shortly afterwards.

Want to learn more about technologies made for space and used on Earth? Check out NASA Spinoff to find products and services that wouldn’t exist without space exploration.

Make sure to follow us on Tumblr for your regular dose of space!

2K notes

·

View notes

Link

Get the best SMT and SMD Reflow Services in Gandhinagar and Ahmedabad, India. Our experienced team delivers fast, efficient, and high-quality results. Contact us now to get started!

Our services play a crucial role in the production of process control instruments for industrial and commercial applications, such as temperature, pressure, and flow control solutions.

#smd reflow#surface mountain device#smt#electronics manufacturing service#pcb contract manufacturing#pcb assembly#pcb soldering#pcb wave-soldering in ahmedabad#gandhinagar#ahmedabad#electronics industry#electronics in gandhinagar

0 notes

Text

Revolutionizing Aerospace Manufacturing: The Power of Advanced Technologies in Combustion Liner Production

In the dynamic and challenging landscape of aerospace manufacturing, the production of combustion liners stands as a critical component that demands utmost precision and reliability. A visionary team of engineers set out on a transformational journey to revolutionize the industry's approach to manufacturing aerospace combustion liners. By addressing complex challenges head-on, they not only resolved existing issues, but also propelled the company towards unparalleled success. This blog unveils their strategic triumphs and the remarkable impact created while providing actionable insights to optimize aerospace combustion liner production.

Unraveling Opportunities and Ingenious Solutions:

A Thorough Foundation: The journey began with a meticulous analysis of the initial input study for combustion liners, complemented by a comprehensive gap analysis. By identifying potential failure points and aligning processes with precise engineering requirements, the team laid a solid foundation for their subsequent endeavors.

Streamlined Process Design: Armed with invaluable insights, the team crafted an ingenious process design that maximized efficiency and accuracy in manufacturing combustion liners. An intuitive process flow diagram provided a holistic view of the production process, allowing the team to pinpoint optimization opportunities and enhance combustion liner quality.

Stage-Wise Manufacturing Mastery: A groundbreaking stage-wise manufacturing process emerged, comprising individual components of combustion liners, precise sub-assembly, and the final assembly of the combustion liner. Empowered by process-controlled tools featuring a foolproof poke-yoke mechanism, errors were minimized, and productivity soared.

Elevating Quality with CTQ Inspection Gauges: To surpass customer expectations and stringent aerospace standards, the team introduced stage-wise inspection gauges for Critical to Quality (CTQ) aspects in combustion liners. These precision tools became guardians of uncompromising quality, ensuring the final combustion liners met rigorous performance requirements. A Symphony of Control: A meticulously crafted control plan was orchestrated, harmoniously linking each manufacturing step of combustion liners to key inspections. This symphony of control guaranteed a flawless production process, eliminating rework and costly delays. Mastering Welding Challenges: Recognizing welding's significance in combustion liners, the team established a state-of-the-art welding cell. Welding operators underwent rigorous training and qualification, ensuring precision and consistency in every weld to enhance the combustion liner's structural integrity. The Crucible of Brazing and Heat Treating: Critical brazing and heat treatment processes found perfection under the watchful eye of a reliable and qualified source. These pivotal steps culminated in aerospace combustion liners of uncompromising durability and performance, ensuring optimal operation under demanding conditions.

Unleashing the Impact:

Time-Defying Triumph: The transformational project delivered combustion liners with exceptional efficiency, setting a new benchmark for aerospace manufacturing timelines.

Scaling Heights: With streamlined processes and enhanced capabilities, the team achieved awe-inspiring success by producing a considerable number of combustion liners. The optimized workflow exhibited its scalability and adaptability, driving productivity to soaring heights.

NADCAP-Certified Excellence: The pinnacle of achievements was the coveted NADCAP certification earned for the manufacturing of aerospace combustion liners. This prestigious recognition solidified the company's reputation as a trailblazer in combustion liner production.

Conclusion:

The journey of revolutionizing aerospace combustion liners showcased the potential and bold implementation. By harnessing the power of streamlined processes, meticulous quality control, and a dedicated team, the company realized exponential growth and customer satisfaction in aerospace combustion liner manufacturing.

To embark on your own path of transformation, embrace a holistic approach to process optimization, leverage NPI technologies, and invest in nurturing a skilled and committed workforce. In the ever-evolving aerospace industry, adaptation and continuous improvement are the wings that will propel you towards unrivaled success in aerospace combustion liner production. Now is the time to soar to new heights and unlock the true potential of your combustion liner endeavors.

#electronics#electronic manufacturer#quality#innovation#ems industry#manufacturing#ems company#industry#ems india#electronic contract manufacturing#Aerospace#aerospace components#aerospace combustion linear#component manufacturer#aerospace electronics#trendy#news#new post#avalontec#avalon#electronic manufacturing services#electronic manufacturing industry#electronic manufacturing company#usa#news of the day#blog

1 note

·

View note

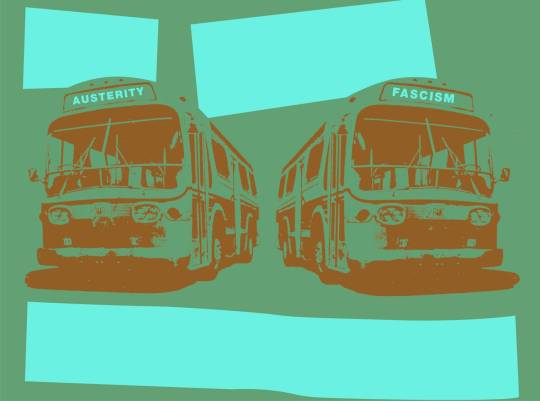

Text

“Did you see that Facebook post about the budget cuts?” my co-worker asks. “What the fuck, no,” I reply. She hands me her phone. I see a headline announcing that, due to the push to slash basic services coming from Elon Musk and Donald Trump, 20% of our funding for local public transportation is now threatened. Lawyers are fighting it out in the courts, but if these cuts go through, it will mean less service, possible layoffs, and lots of people not having access to a system that is one of the few lifelines for poor people in our area. People depend on these buses to get to their jobs, to medical appointments, to programs for special needs adults, to court dates.

I sit back down, staring out the window at the cold, grey parking lot. I am waiting for a member of the morning shift to come in with a bus so I can take it out. A few buses dot the bus yard. They’re sitting idle because the parts on order haven’t come in for months—even years, in some cases—and because the city refuses to hire enough mechanics to keep up with daily maintenance. This means that drivers on night shift, like me, sometimes have to wait hours for a bus to arrive. Our transit agency, which contracts out to a huge multi-national corporation, is already dramatically underfunded. The new cuts will only compound our existing problems.

“Fucking Musk, man,” I say with a sigh. Another co-worker on the night shift agrees with me. He’s in his mid-70s, but he’s still working full time because he recently burned through all his savings burying his parents. I launch into a long rant about how both Musk and Trump hate labor unions and workers and want to replace us all with artificial intelligence. A third co-worker, presumably a Trump supporter, grumbles about how “they” just want to blame the cuts threatening our jobs on the “administration.”

It’s pitch-dark when I enter the trailer park, passing a metal gate, I drive slowly through the ever-growing rows of manufactured homes. Some of them have signs reading “For sale.”

“Lots of people moving out?” I ask my only passenger.

“Yeah, no one can afford to live here anymore,” she replies. As I turn the corner, she launches into a long tirade about the corporation who owns the trailer park and how they keep raising the cost of “space rent,” the monthly fee that mobile home owners pay to trailer park owners. “Every year the rent here goes up. New people move in from out of town and they can pay more, and that’s pushing us out,” she says, as I unhook her walker inside the cold, dark bus cab. “I don’t know why the landlords are so greedy. Do they just want everything?” I lower her and her walker down onto the pavement outside her trailer.

As the electronic ramp whirls its gears, I turn to my left. In her front window, there is a strange collage of images of Donald Trump. It is faded and worn from the sun. I shake my head and chuckle, resisting the temptation to point out the obvious. How can you complain about a corporate landlord ruining your life, but place all of your hopes in another landlord who is trying to become a dictator?

Perhaps she senses my disdain. “Trump is gonna fix it, you’ll see. Prices are going to go down once he starts drilling.”

My eyes narrow. “Biden was drilling more oil than any president before him,” I reply.

I meet all sorts of people like this at my job. One guy smells like piss so bad while I strap in his wheelchair that I have to turn my head so I don’t gag. The car in front of the house where I pick him up has a bumper sticker on it reading, “I Don’t Trust the Liberal Media.” I wonder if the conservative media is telling him his healthcare is about to be nuked from orbit.

Another guy, as I load and unload his wheelchair, takes out his Trump hat, puts it on, and asks me what I think of it. I tell him Trump and Musk want to use the military to shoot protesters, destroy unions, and fire workers like me, so why would I give a fuck about them. He looks away, says, “Alright then,” and jets off on his electronic scooter. I wonder if he is looking forward to ICE deporting half of his neighbors.

On election day, I lost it and got into a heated back and forth with a pro-Trump guy. He rested his case by proclaiming that we need to make it easier on rich people so that the wealth will trickle down to the rest of us. I want to grab these people and shake them.

Trump represents the triumph of the nihilism of our age. The foreclosure of the idea that the working-class can take and shape its own destiny. Instead, apparently, we should throw ourselves at the mercy of a reality TV star who shits in a gold toilet, eats breakfast with billionaire pedophiles, and has dinner with neo-Nazis between rounds of golf. In the absence of the kind of social movements that could connect people and enable them to grow and change, Trump has built a mass parasocial spectacle that makes these isolated people feel like they are part of something greater than themselves even as all of our lives become smaller and smaller, more and more impoverished and alienated.

I shuffle into the union hall, past the placards reading “ON STRIKE” and faded signs several decades old. Almost fifteen years ago, during Occupy, I attended a meeting in this same room. I wonder what’s changed since then. I find a seat and one of our union shop stewards slides a packet across the table to me. I open it up and start paging through it, looking at the spreadsheets and graphs.

We start to discuss the ins and outs of the proposed contract that our elected union representatives and corporate lawyers have been going over during recent meetings. One of the much-hated top corporate bosses was recently fired for corruption, much to the delight of the entire workforce. As one of my co-workers said, “Really tells you a lot about a place when motherfuckers are walking around singing, ‘Ding-dong, the witch is dead!’ and morale has never been higher!”

We go through the contract. Despite a few small improvements, things are mostly the same. “What about the pay?” I ask, fingers crossed. The shop steward cocks her head to the side and turns a page, pointing with her pen to a graph showing a dollar increase. She explains that the contract will be for five years, during which time we’ll only be getting a few cents more each year. “This is literally what I was making ten years ago,” I sigh, “and this contract will be valid for five years?”

I already can’t save money. Imagine what things will be like in five years.

She shrugs. “We’re encouraging you to vote “Yes,”’ she says, and hands me a piece of paper on which to mark an “X” signifying yes or no.

If enough workers vote the contract through, the company will ratify it and it will govern my life for the next five years—presuming that I don’t get downsized. Any strike or protest activity will be illegal, as per our “No Strike” agreement. If enough people vote no, it goes back to the union bargaining team, and they will continue to bargain for more changes in closed door meetings.

I head into another room, mark an X by “NO,” and drop the piece of paper into a wooden box. I wave to a few co-workers on my way out. As I leave, I pass a portrait of Sean O’Brien, the president of the Teamsters union. You smug bastard, I say to myself. I remember his glasses and bald head on stage of the Republican National Convention last year, when he called Donald Trump a “Tough son of a bitch.” What a dipshit.

I used to have a poster in my room many years ago, proclaiming, “The past doesn’t pass.” Next to the slogan was a photo of striking Teamster bus drivers—bus drivers, just like me—beating police officers with baseball bats during the general strike of 1934 in Minneapolis. That was one of the decisive labor battles that forced the ruling class to accept the New Deal in order to cool down the class war that was brewing on the streets.

At home, I look over a letter announcing that people in my neighborhood shouldn’t drink the tap water because the levels of uranium in the river are too high. Sometimes I wonder what I would say to my children about this moment in history—if I could afford to have children. Probably the same things my parents say to me now: they’re sorry we are inheriting this world. Sorry they didn’t fix it. Sorry they didn’t build strong enough movements to turn the tide against these monsters.

At work, as I drive, I begin to notice that there are fewer Trump flags and signs out. Resentment is rising. A joke by a cashier here about being replaced by AI, a comment there about Trump cutting programs. I walk into the break room and someone is shaking their head angrily while watching a video of Musk on their phone. They mutter something about tariffs and rising prices.

The tension in the air is palpable. It is similar to how things felt at the start of the economic crisis in 2008, when many of the homes in my neighborhood were foreclosed on and many people lost their jobs. It also reminds me of the start of the pandemic—how at first, I thought it wouldn’t be so bad, only to watch in horror as our family members and friends succumbed to the virus.

In 2008, many people thought that crowds would flood the streets immediately when the administration bailed out the banks while leaving the rest of us high and dry. That didn’t happen. It took years for resistance to grow. In Chicago, workers occupied their factory when they were terminated without pay. In Wisconsin, workers occupied the capitol building against government attacks on collective bargaining. In California, students occupied universities to protest budget cuts. The Occupy movement began in the fall of 2011 and rapidly built to massive occupations of city squares across the US, coordinated port shut downs, and a general strike in Oakland, California. With Joe Biden as vice president, the federal government helped to coordinate violent raids targeting the movement in order to break it apart.

In 2020, on the other hand, things didn’t fester���they exploded like a bomb. Millions of people across the country mobilized in response to the pandemic, providing mutual aid in the face of government inaction and right-wing disinformation, and then hit the streets in the George Floyd uprising.

Who knows how things will evolve this time. It will probably be different from both of those scenarios, but it could be similar in some ways. What is clear is that things are not as people expected them to be. Many people on the left thought—or at least hoped—that Trump would govern the way he did the first time, constrained by mass protest, the courts, and his own party. Many who voted for him honestly did not expect him to follow through on many of the policies he explicitly promised to carry out. Those who were not paying attention are surprised that suddenly, jobs are disappearing and services are being cut while prices only continue to rise.

The material conditions are forcing people to reckon with the fact that the state is attempting to reshape our lives for the sake of an authoritarian project. As we speak, thousands of people are flooding town halls across the United States, screaming at their so-called representatives about the plan to gut programs like Medicaid—only to hear the bureaucrats repeat a slew of MAGA talking points. Anger is brewing. Hopefully the MAGA strategy of “flooding the zone” with shit will produce diminishing returns as people turn towards their neighbors and co-workers and away from their phones and YouTube.

This is an opportunity for us to call out the authoritarian project of the Trump administration, the techno-dystopian fantasies of billionaires like Musk, and the complicity of the Democrats who helped make all of this possible. Beyond naming the systems that we are up against, we also need to be clear about our position as workers and how the billionaires running the country want both to hurt us and to weaponize our anger, turning us against each other through propaganda and fearmongering. This is why it’s important to stand in solidarity with everyone attacked by the Trump administration, whether trans folks, migrants, prisoners, or beyond. We can’t leave anyone behind. The only immigrant trying to steal my job is Elon Musk. It’s time to be clear that our interests are not theirs; we must develop and promote our own vision of a better world in total opposition to the ruling class, the billionaires, and their fascist puppets.

Moreover, it’s time for action. We need to give expression to these antagonisms while revealing the poverty of the institutional forms currently at our disposal—the Democratic party, the ever-shrinking union bureaucracy, the non-profits. We can show examples of past struggles and resistance from the mass wildcat strikes by teachers in West Virginia and the fierce anti-fascist mobilizations against the alt-right to the airport shutdowns following the Muslim Ban. We can support and expand the existing fronts that are already breaking out around us: protests against Musk outside of Tesla, rallies to demand that hospitals continue to treat trans people, community defense and rapid response networks to address ICE attacks, bashing back against the violence of the far right. We can demonstrate the utility of tactics and strategies that others can take up and expand on as all of us figure out how to fight in the new reality.

It’s hard to look at the news without imagining tanks on the streets or scenes out of V for Vendetta. But the scenario I worry about most is that this will simply become the new normal. That we will accept this just as we accepted the last round of attacks. As we accepted the genocide in Gaza. As we accepted the ecological gun to our heads that is climate change.

While people are angry and energized, we have a chance to push in a new direction. Let’s use this moment to foster broad and popular networks of resistance that improve our lives, strengthen our communities, and enable us to meet our needs directly. At this point, we don’t have much of a choice.

Like it or not, this is life now—and it is coming for all of us.

-“The Only Immigrant Trying to Steal My Job Is Elon Musk” A Bus Driver’s Perspective on Elon Musk’s Austerity Measures

37 notes

·

View notes